Home/ABOUT US

| About GILDdesign |

|

|

Starting with smartphone cases machined from a solid block of high-strength duralumin used in aircraft and automobile parts, we develop, manufacture and sell business card cases and ID card cases. Also, we are particular about "Made in Japan," so that the customer can use them with confidence. All parts used in the case, from materials and packages to accessory parts that come with the product, are made in Japan. |

| A Look at the Company |

| How we got started manufacturing smartphones |

|

| We "truly" protect customers' smartphones. We started manufacturing smartphone cases because half of the employees had experiences of breaking the smartphone's LCD screen. Even now, I still cannot forget the feeling of when I broke my important smartphone. Starting with "I never want to break it again," I manufactured after hours the machined duralumin case for the first time, not for business purposes but for the employees. |

|

Our "passion" for products is second to none. After that, many acquaintances started saying "I want it!" through word-of-mouth. We decided to commercialize the product because We "want many customers to use this case!" In the future, GILDdesign will continue to create products for customers when we hear "I want it!" from them. |

| Design Concept of GILDdesign |

|

| "Keep what is necessary and remove what is unnecessary." GILDdesign's is a company which designs and manufactures parts for bicycle races. For races, we try to reduce the weight while keeping the required strength. Gilddesign's products are designed by keeping what is necessary and removing what is unnecessary. |

|

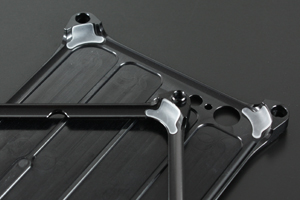

"Functional beauty" is born there. For example, the reason why four corners of GILDdesign's smartphone case are sticking out is not simply due to the visual design. It is designed with the "necessary thickness" to absorb the impact from the four corners when it is dropped. We work on making products which utilize the technology and experience cultivated from the design and manufacture of racing parts. |

| Particular about ALL MADE IN JAPAN |

|

|

|

|

| We are particular about the aluminum case of GILDdesign being made with parts that are all "MADE IN JAPAN." Everything related to the aluminum case, including the surface treatment, bolts to fix the case, supplied silicon, wrench and even the box packaging, not to mention the machining which finishes off a solid block of high rigidity duralumin into an aluminum case, is made in Japan. Thorough commitment to "MADE IN JAPAN" leads to confidence in the case by customers who can use it with peace of mind. Please experience "high quality" which only can be achieved by using reliable "Made in Japan" products. |

| Carefully Selected Materials and Functionality |

|

|

|

|

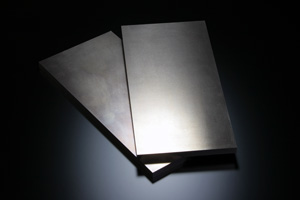

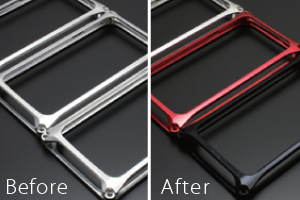

Using a solid block of duralumin A2017S made in Japan by Furukawa Electric Co., Ltd., the design and development and repeated testing were done in-house which resulted in a smartphone case that was lightweight and highly rigid. A2017S is used for aircraft and automotive parts and is characterized by high strength and good machinability as well. Also, the interior wall is lightened using 3D cad/cam because the smartphone case has to be lightweight while maintaining its strength. Moreover, it is processed according to the shape of the smartphone through 3D processing. The size of each part is determined without impairing the design so that all operations can be done smoothly. An alumite treatment is done for the surface treatment to form a hard film and increase strength and durability further. |

| How We Make Duralumin Cases | |||

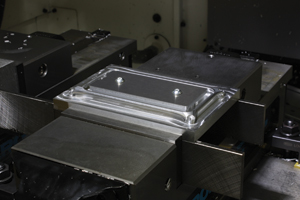

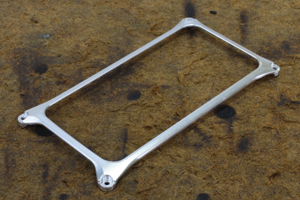

| We carefully cut from one aluminum block and take time to finish it with care because it is something that has to be used every day. |

|||

|

|

|

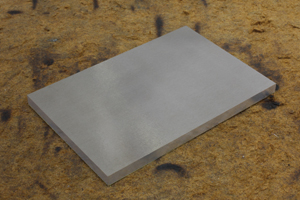

| 1. Material before it becomes a case. | 2. Tools needed to machine a case. | 3. Attach it to jig and cut it by machining. |

|

|

|

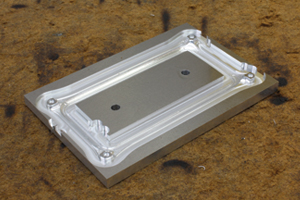

| 4. The stage of the first process for the back of the case. | 5. Attach it to jig again and machine the opposite side. | 6. It takes 20 minutes until machining of the back side is complete. The same process is repeated for the LCD side. |

|

|

|

|

| 7. As machining is completed on the LCD side and the back side, it is colored by alumite treatment. | 8. After finishing the alumite treatment, all pieces are inspected, assembled and hand-packed one by one. | 9. It is put into a decorative box. Then, it is delivered to customers. | |

| A machining center is a big machine which costs approximately ¥10million ~ 15 million. Only 20 cases are manufactured each day, however, only by taking time can high quality cases be manufactured. |

|||

English

English Japanese

Japanese