|

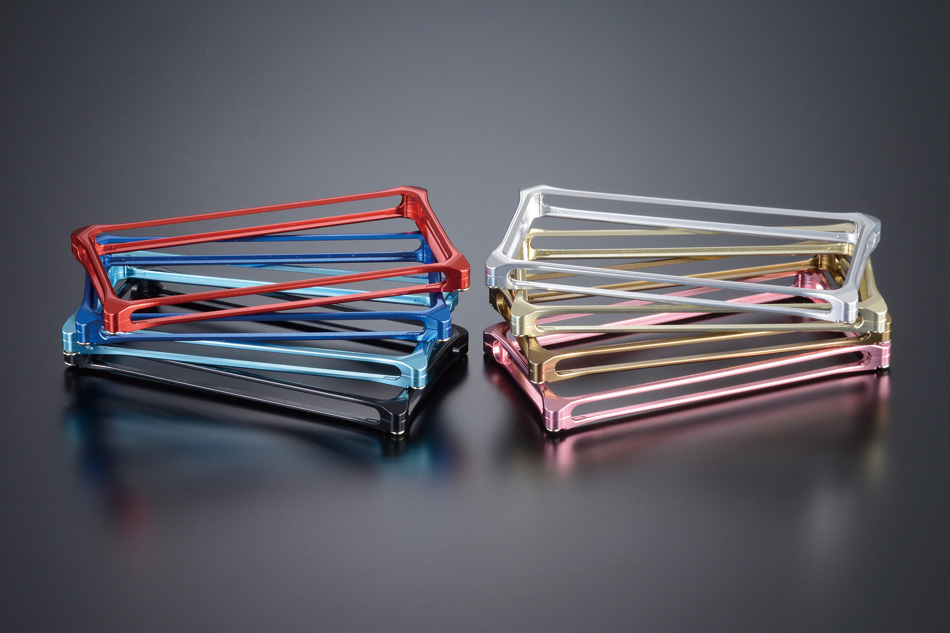

GILD design has the policy of having all the materials processes for the aluminum case MADE IN JAPAN.

From using High rigidity raw material of duralumin, the milling process, the surface treatment,

the screws, the shock absorber silic one sheets, the wrench to the packaging.

All the process, and the materials used making our case are all made in Japan.

This policy gives us the confidence that we can provide a case to the customers that they can surely trust.

We would like you to experience high quality by using a trusted product from Japan. |

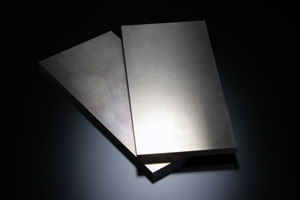

Duralumin is a material which combines strength and lightweight. |

|

The body of the case is accurately made from the material called A2017

also known as Duralumin, a material which has light weight and strength.

It is also used for making aerospace and racing parts.

We are using a high quality A2017 duralumin made by Furukawa Denkou. |

| |

The process of making a duralumin case |

Milled delicately from a piece of aluminum |

|

|

|

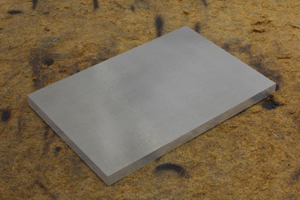

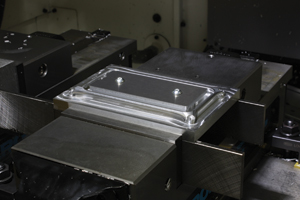

1.Raw material of the case |

2.The milling tools |

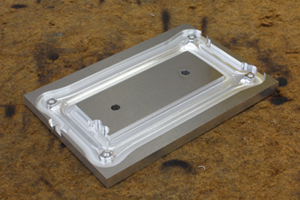

3.Attached to a jig, and run the machine. |

|

|

|

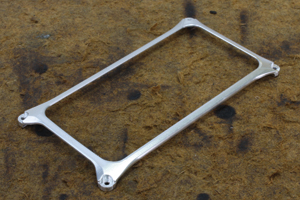

4.The first process of the back

part of the case is finished. |

5.Attach to another jig to mill

the opposite side. |

6.It will take about 20mins to finish

the back side. The same process

will be done to the front side. |

|

|

|

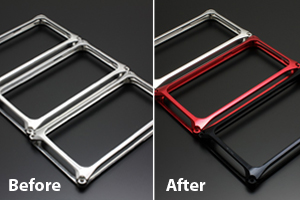

7.After the machining process.

It will get anodized for coloring. |

8.After anodizing, it will be

checked, assembled, and packed

by humanhands. |

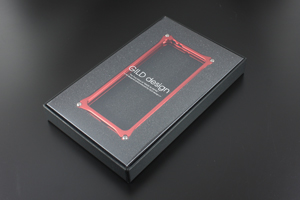

9.Packed and goes to the customer’s hands. |

|

A single machining center cost about 10 to 15 million JPY ※100,000 to 150,000 USD

One machining center can produce only 20 cases per day, but by giving time

this leads to a high quality cases. |

| |

| From the attachments to the packaging box are all made in Japan. |

|

|

|

|

| Torx type stainless screw |

Using a high shock

absorbing elastomer |

Exclusive wrench |

Box designed to prevent

the case from damage. |

| The reason we use made in Japan is to make people feel secure, and to feel Japan’s

technology. |

|

English

English Japanese

Japanese